-40%

YZ450F Cylinder Head Service complete with upgrade Titanium valves

$ 421.87

- Description

- Size Guide

Description

Fastheads.com deals exclusively in motocross cylinder heads and valve train components for all brands. We machine, repair and service worn or damaged heads with the latest high tech equipment designed for high RPM multi valve heads. Old school methods of valve seat re-facing or grinding will not work on these new heads! Our primary goal is incredible reliability and reduced valve wear while maintaining stock or more power. We do this by using compatible alloys, DLC type valve coatings and precise machining for perfect valve to seat concentricity. Pick from many options including economy trail to full on race packages to meet your needs.This Ebay item is our most popular complete YZF rebuild package. Upon arrival the valve train is remove, the head is then cleaned by soda blasting and inspected for all needed repairs.

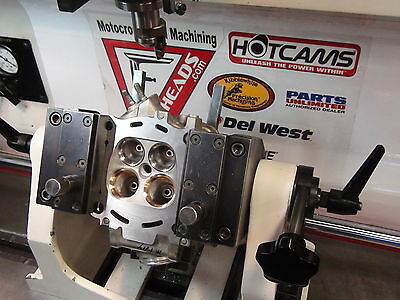

The seats are cut with a multi angle high flow profile on our race designed Rottler SG7 seat and guide machine for precise concentricity every time.

Your head is then professionally assembled, spring and stem heights are checked and corrected, gasket surface is checked and corrected and vacuum tested for a perfect seal.

Parts included, Del West CrN PVD coated Ti valves, OEM valve springs and Viton guide seals. If it needs guides we can replace for an extra charge.

For more we can adjust the valve shims.

Note: For a more economical package we also offer Stainless steel valves with a matching spring kit for 9.00. The heavier valves reduce output by 2 horse power and absolutely requires the stronger springs to control the extra valve weight. The stock seat material was not designed for SS valves. Complete porting for 0 more.

Give us a call with your needs and we will estimate the cost. Normal turnaround time is 7 days.

Check out our ebay store

for rebuild tools, shims, services and parts.

Call for options and any questions.

Remember, if your valves are worn out so is your seat surface. New valve surface on a rounded seat results in a very thin contact area resulting in fast wear and less heat exchange.

We only cut seats to match new valves. You can either supply yours or buy ours. We offer a wide variety of valves in stainless or titanium, guide seals and spring kits to match your needs. If you want an endurance or the Ultimate race head we can build it. We also offer porting at a reduced price when purchased at the same time. Dealers and race teams are welcome. We use the new race developed Rottler SG7 seat and guide machine specially designed for these type of race heads.

Please check out our ebay store for complete engine rebuilding, seat cutting/maintenance, rebuilding parts and tools.

Send your heads and engines to: Fastheads, 1141 E 540 N #6, Saint George, UT 84770

We operate one of the largest mail order type services for complete engine, transmission and head rebuilding for the Motocross Off Road Community. It's our specialty so we can save you money and headaches. See us at the WORCS races and other events around the west. The owner races and has been involved with the technical aspects of engine building for the last 38 Years.

WORN VALVE SEATS HAVE TO BE RE-CUT OR FACED IN ORDER TO DECREASE NEW VALVE WEAR AND MAINTAIN PERFORMANCE. MOTOCROSS HEADS REQUIRE NEW MACHINING TECHNIQUES.

Specialized machining techniques have been developed in order to cut seats in current motocross and other small engine race style multi valve heads. This is everything you need know in order to grasp the concept of how and way valve seat concentricity is critical in performance, wear and reliability and why old school methods of seat cutting do not work.

All valve seats are cut by installing a pilot shaft in the guide in which the cutting tool centers and revolves around.

The seat has to be accurately cut horizontal and vertical to the centerline of the valve guide.

Concentricity is how perfect this measurement is.

Poor concentricity will let one side of the valve land on the high side of the seat face first.

Depending on the severity of the seat face offset the valve may always be open on the low side or the valve may flex or slide to center from the force of the valve spring.

Guides wear oval front to back and may let the pilot move in the same pattern which can also create poor concentricity on the seat radius.

Imagine now, how non-concentric seats can affect the ability for the valve to seal under pressure, how it increases valve wear, how it decreases the ability for the valve to transfer heat to the seat and how the valve stem being flexed every time the valve closes can create it to break.

The following is a description on why it is nearly impossible to maintain concentricity using old machining methods on newer race heads.

1.

Valve stems and the guides are much smaller in diameter.

From 7-8mm to 4-5.5mm.

The smaller pilot shaft needed to fit in the guide decreases its ability to withstand flex thus allowing the cutter to follow the old seat face.

2.

The distance from the top of the guide to the seat face has increased due to a much larger port which has allows the pilot to flex even more.

3.

Some race seat face profiles requires the cutter to cut more surface at one time along its cutting edge which create more force against the pilot.

Modern machining equipment has been created to adapt to the pilot flex problems.

Most early four strokes were low rpm utility engines and had large enough pilot to enable the use of hand operated cutter and grinders with some degree of accuracy.

They would run and start even if the concentricity was off compared to the tolerances required in race motors.

Most motorcycle shops cut valve seats using these hand tools such as a“Neway cutter” and didn’t realize the need for perfect concentricity until their work immediately started to fail.

Except for race technicians most mechanics don’t even know what a concentricity gauge looks like.

One major cure was to use stiffer pilots made of carbide instead of tool steel to reduce flex.

This still didn’t give us the concentricity requirements with hand operated cutting tools.

The only way to make concentric cuts with small pilots is to perfectly support the pilot from the top and guide side.

This requires the purchase of a ,000 or more air float seat and guide machine.

Not to many shops will spring for that type of equipment and most mechanics if they are educated on the importance of concentric seats and its effects on reliability will send them to a professional race machine shop that deals in small valve stem seat cutting.

On Apr-05-08 at 17:49:47 PDT, seller added the following information:

After purchasing, pay instantly with your credit card through PayPal!

Froo www.froo.com | Froo Cross Sell, Free Cross Sell, Cross promote, eBay Marketing, eBay listing Apps, eBay Apps, eBay Application